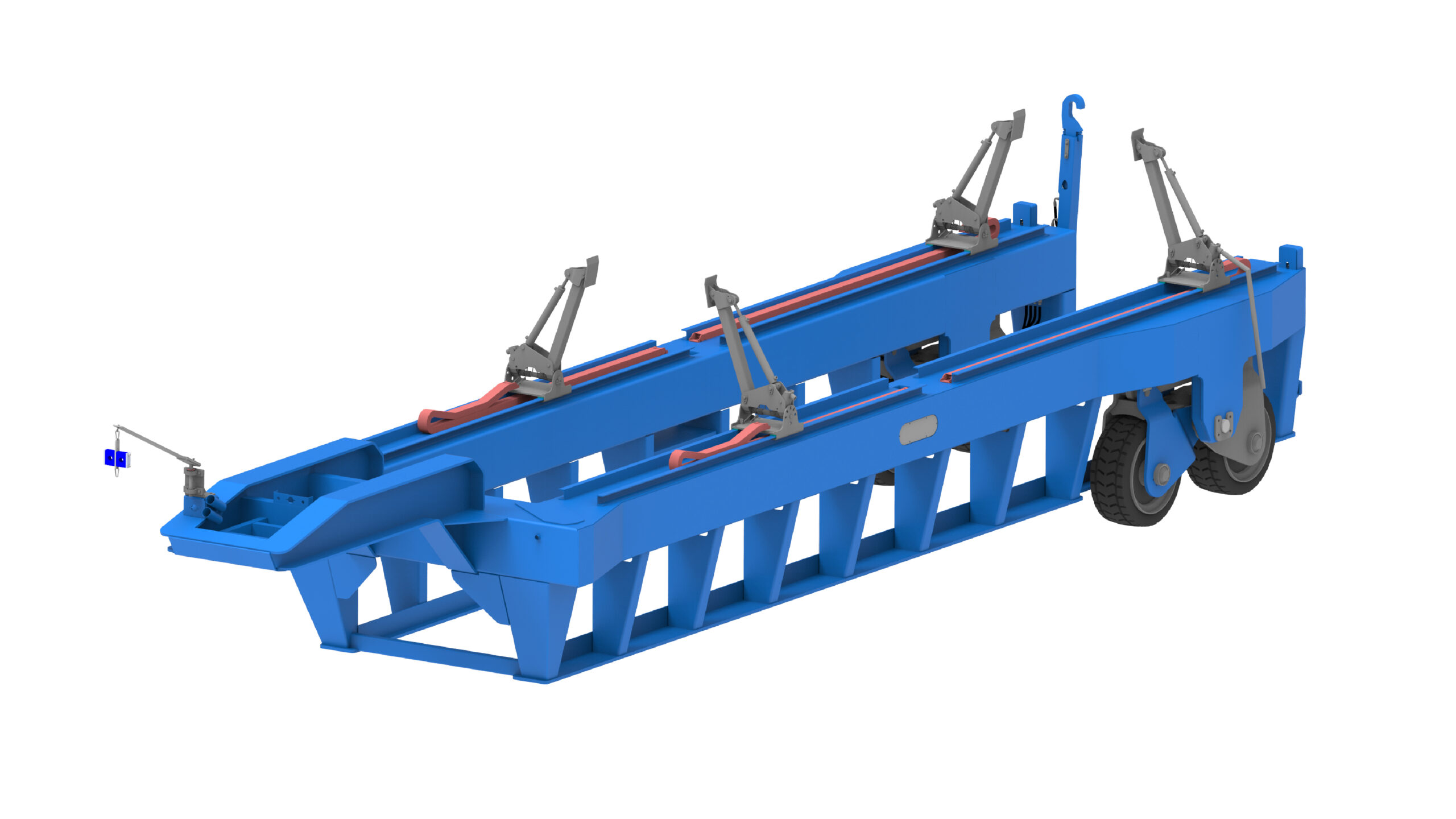

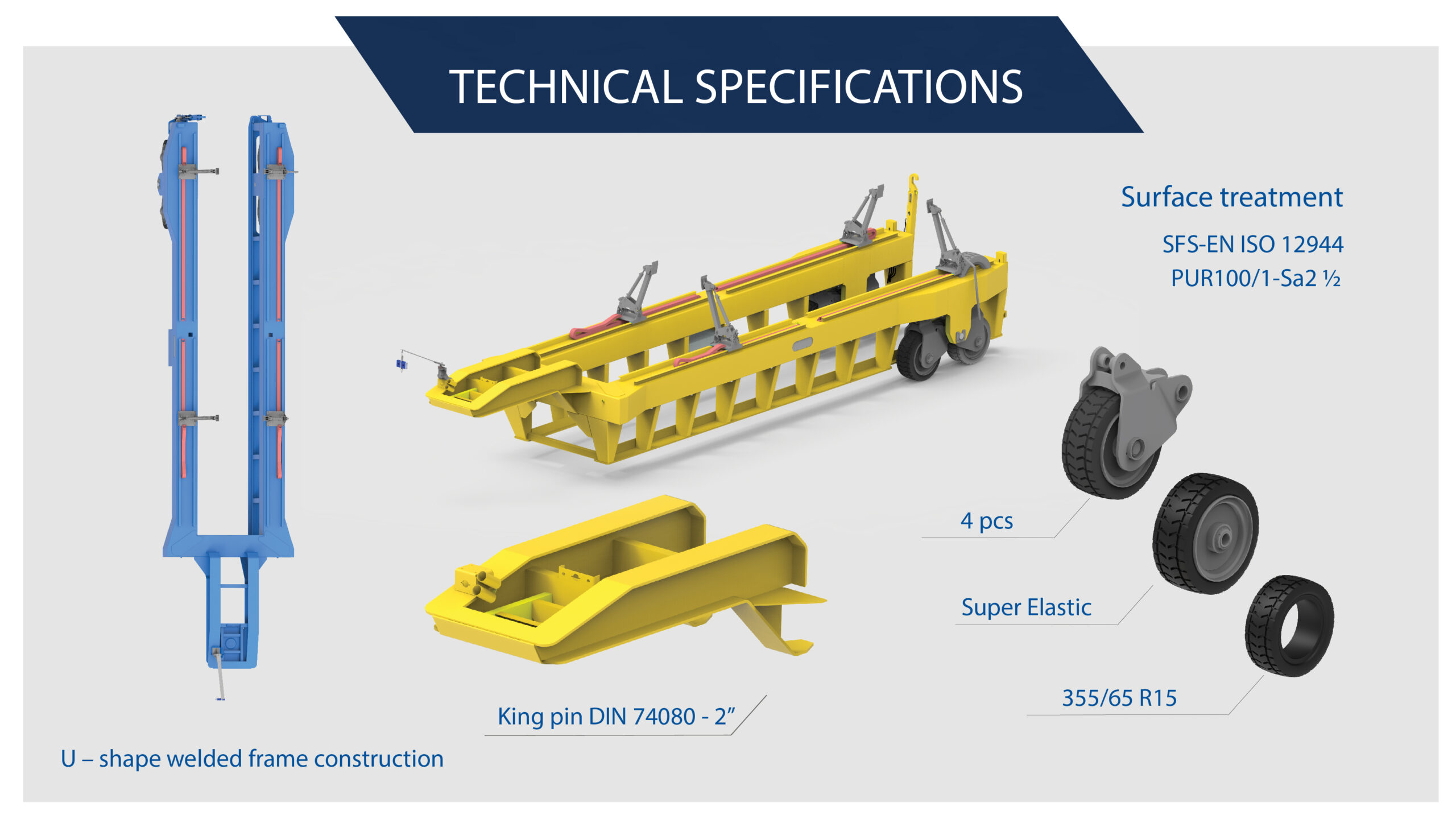

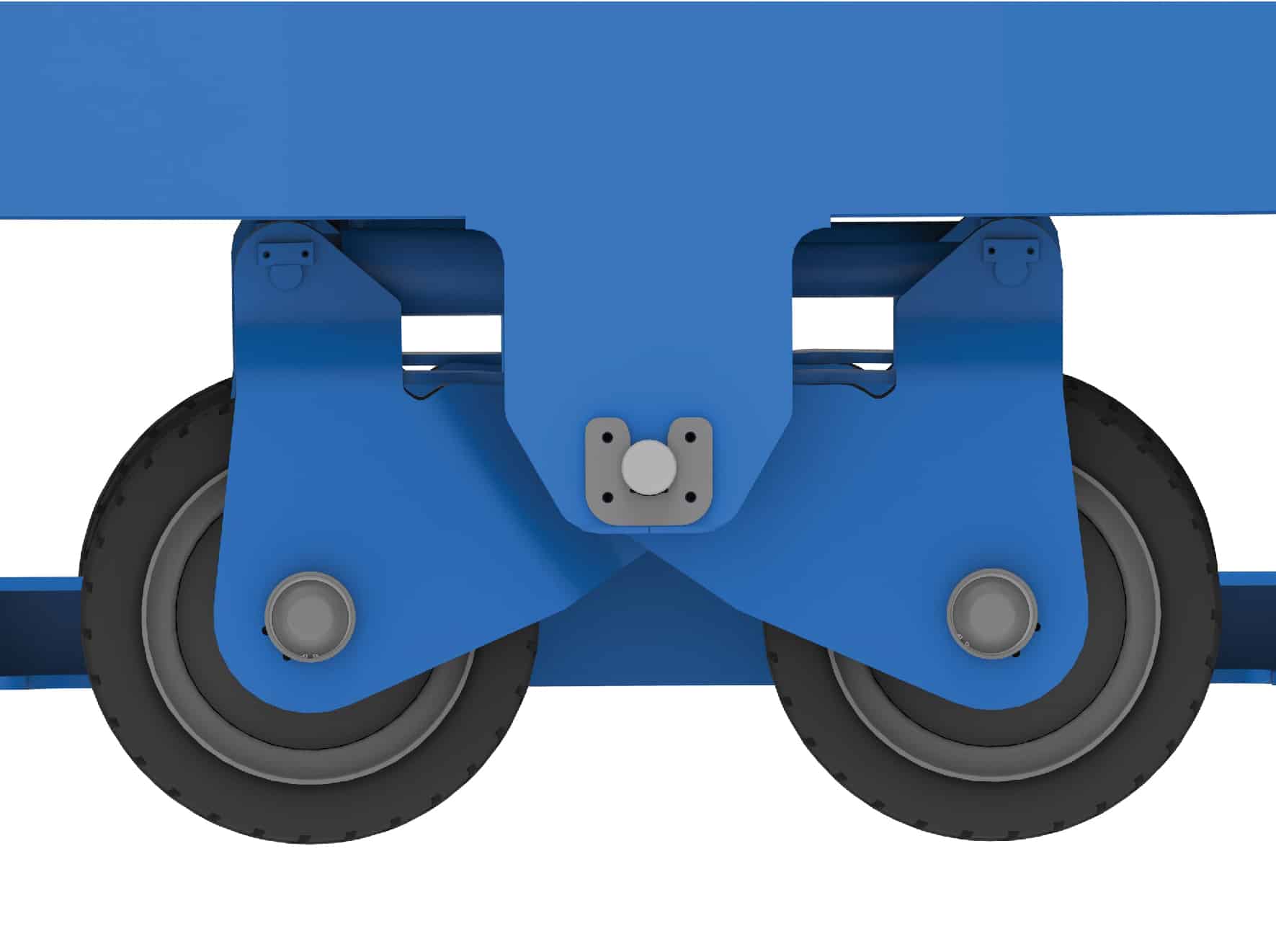

Design is based on our new scissor suspension system. A double-wishbone suspension is used on both sides. One single pivot point with hydraulic cylinder for lifting and lowering the load. Solution allows for effective work, and high responsiveness to terrain unevenness. Thanks to the use of one axle, the suspension also adjusts to the angle of the terrain.

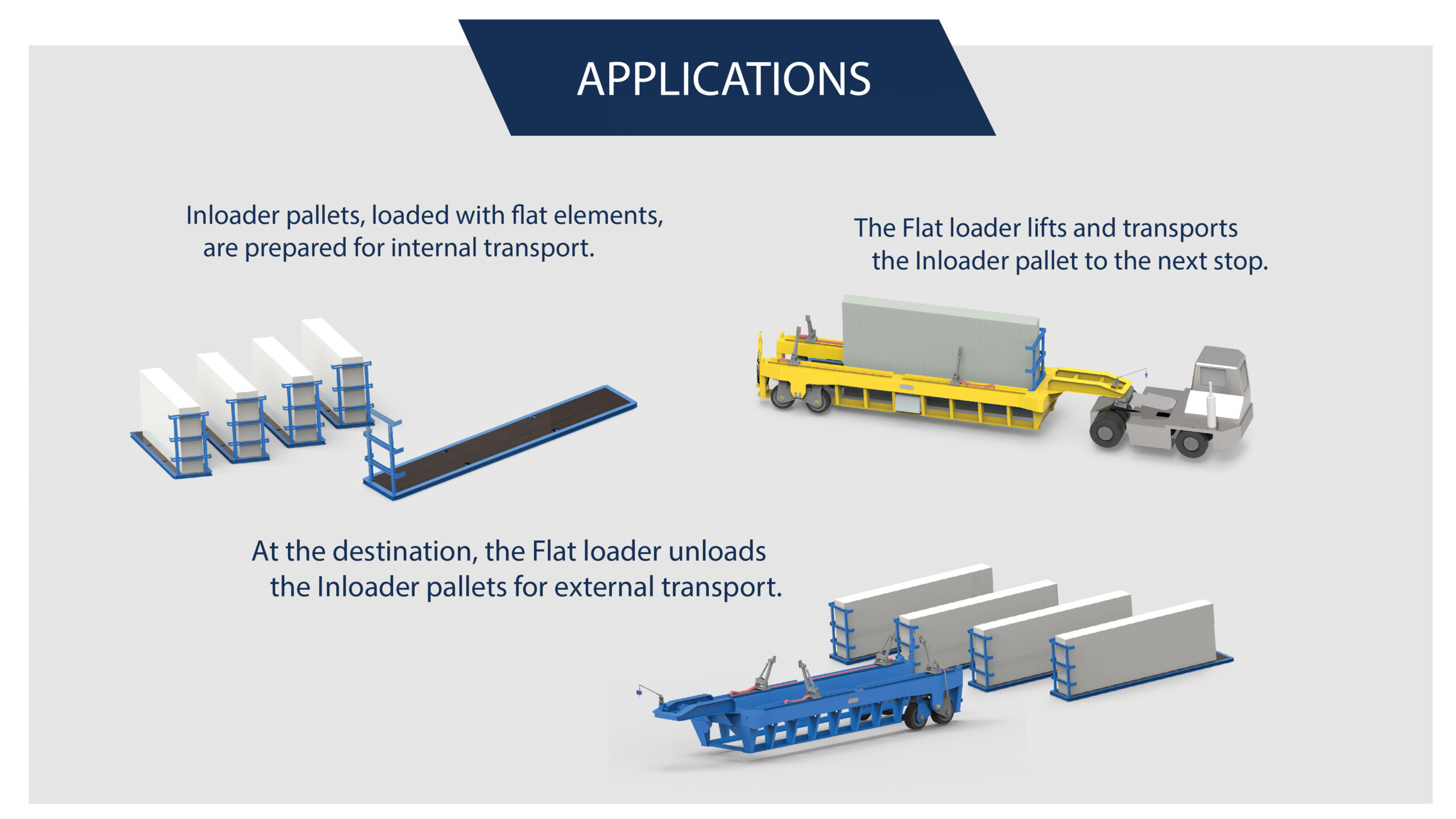

Four hydraulic arms, for stabilizing the load, can be adjusted manually in any configuration. After manually setting the arms in the required position, the hydraulic system clamps the arms, stabilizing the load. Thanks to the use of special slides that move along the guides, after tightening the arms they remain locked, protecting against uncontrolled front-back movement.

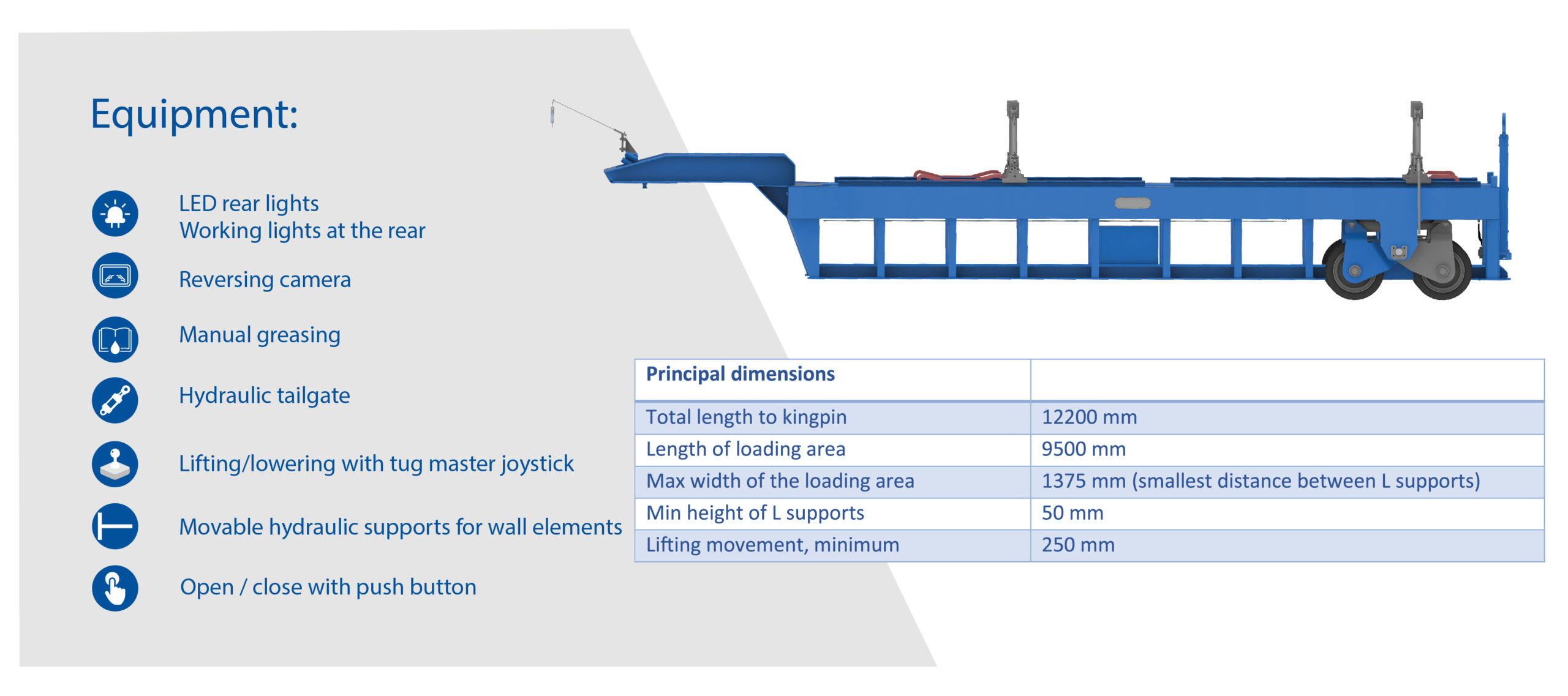

Rear safety beam is closing between the sides using a hydraulic cylinder. Beam closing system is equipped with a sequential hook lock. After closing the beam, the hook is additionally pressed automatically. Thanks to this, the load and the structure are secured in the best possible way. The opening takes place in reverse – the hook is unlocked, and then the beam is lifted. The system has additional protection against use of a flat loader without a closed rear beam. The system is fully automatic, and the entire sequence, including pressing the hook, is controlled by one button. Rear gate security system and gooseneck

alarm lights available as option.

The structure uses 20 lifting brackets arranged perpendicularly. They ensure the highest stiffness and protect the structure against twisting or bending. The frame in contact with the ground is secured with a slide made of abrasionresistant SSAB Hardox 400 steel. Flat loader is self-supporting and can be placed away without any additional supports or racks. The slide is located on the entire surface of the frame from the bottom. Thanks to this solution, the wheels and all parts of the running gear are protected not only from the inside against damage by the load, but also against collision with the element behind the Flat

Loader. Technological ports are designed along the entire length of the frame.

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form or email or call one of our engineers directly. We look forward to hearing from you.