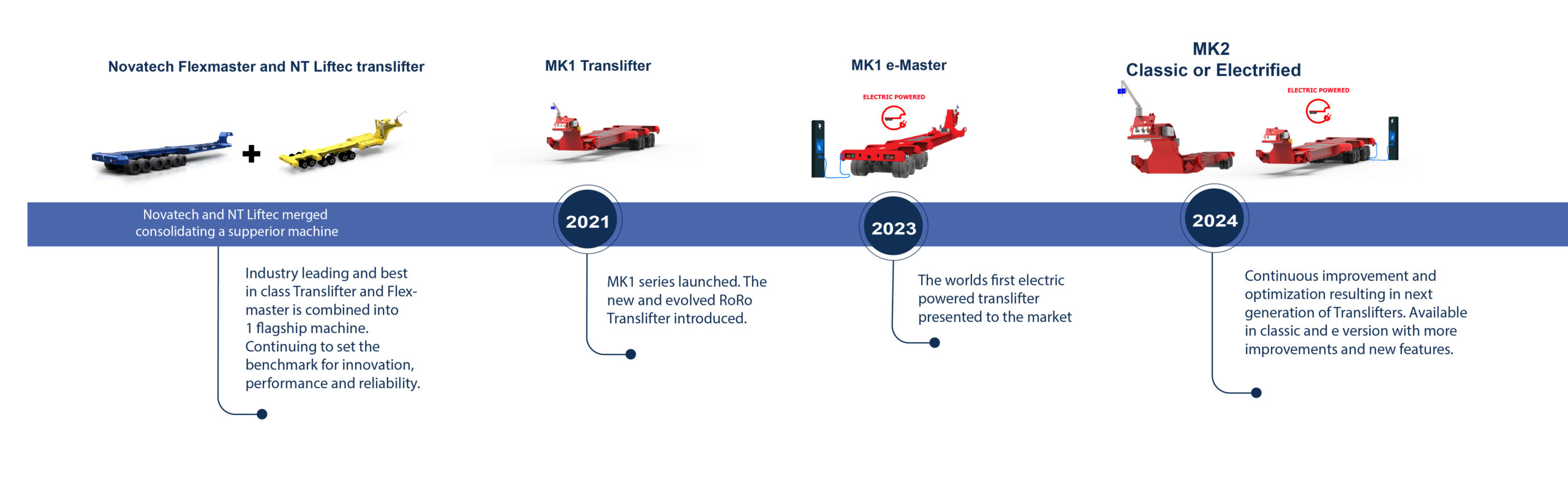

We introduce MK2 e-Master & MK2 Classic based on the proven concept of the MK1 Translifter and recent launched electrified MK1 e-Master. With massive new improvements and brilliant new features, we are ready to introduce the MK2 series from 2024 in classic and e versions.

Introducing the MK2 e-Master:

Your Gateway to a Greener and More Efficient Material Handling Solution

The MK2 e-Master builds upon the trusted MK1 Translifter design, seamlessly integrating battery electric power to revolutionize your material handling operations. With a sleek, compact power package, this innovation eliminates the need for hydraulic flow from the terminal tractor, reducing both energy consumption and emissions while delivering unparalleled performance. Here are the game-changing optional features that will surely capture your attention:

| 1. Extended Operation Time and Enhanced Performance: The MK2 e-Master boasts a maintenance- free low voltage Li-Ion battery package, featuring clever energy recovery and a redesigned hydraulic circuit. This results in over 24 hours* of continuous operation with performance levels that rival or surpass conventional translifters. Experience an uninterrupted workflow with the freedom of electric power. |

| 2. Convenient Charging: Recharging the battery is a breeze. Simply connect it to a standard 230VAC 16A power supply – no special charging infrastructure required. An indicative charging time of just 8 hours after 24 hours* of operation (or 14 hours from empty to full battery) keeps your operations running smoothly without prolonged downtime. |

| 3. Advanced Control and Connectivity: The MK1 e-Master features a brand-new control unit and dynamic display, providing a user-friendly interface to the control system. For enhanced visibility and remote monitoring, consider the optional Wiselink 4G/5G remote connection. Track the live location and status of your MK2 e-Master through a web portal, which also offers in-depth statistics on machine performance and the ability to review alerts and alarms. |

| 4. Efficient Bogie Drive: Opt for the optional one bogie drive feature, which not only conserves driving energy, but also reduces tire wear. This feature introduces a bogie maintenance mode, allowing independent lifting of bogies for simplified servicing. |

| 5. Safety and Awareness: The inclusion of a new reverse camera with human recognition feature enhances on-site safety. It provides timely warnings to the operator if anyone enters the danger zone during reversing, ensuring a secure working environment. |

| 6. Termo sensors: Termo sensors installations for protection of hydraulic oil and brakes from overheating. |

| 7. Winter protection. For cold areas oil heating for starting/ running machine with controlled oil temperature. |

| 8. Next-Generation Load Control: For precision in load management, consider the optional next-generation load control system. This system calculates the total load and load distribution between bogies and gooseneck independently, without relying on input from the terminal tractor. It guides the operator on optimal load distribution and prevents unintentional overloading, enhancing both safety and efficiency. |

The MK2 e-Master is not just an upgrade; it’s a transformative solution that aligns your operations with a sustainable future while delivering unparalleled performance and ease of use. Don’t miss this opportunity to enhance your material handling processes with our cutting-edge e-Master.

MK2 series

| MK1 | MK2 Classic | MK2 e-Master | |

| Universal frame | X | X | |

| Extended Operation Time and Enhanced Performance | X | ||

| Convenient Charging | X | ||

| WEB connections 4G/5G | X | X | |

| Efficient Bogie Drive (Optional): | X | X | |

| Human recognition system | X | X | |

| Overheating control | X | X | |

| Winter protection | X | X | |

| Load control | X | X |

IMPORTANT NOTEs.

All orders delivered in 2024 will be version MK2 unless specific ordered.

All classic MK2 can later be upgraded for e-Master.

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form or email or call one of our engineers directly. We look forward to hearing from you.